Vibrating rubber screen mesh is a game-changer for industries requiring robust and flexible material separation. Engineered from premium-grade rubber compounds, these screens excel in high-impact environments, offering unmatched durability, vibration resistance, and precise particle sizing. Whether for mining, aggregate processing, or recycling, our rubber screen mesh ensures longevity, reduced maintenance costs, and seamless operation under extreme conditions.

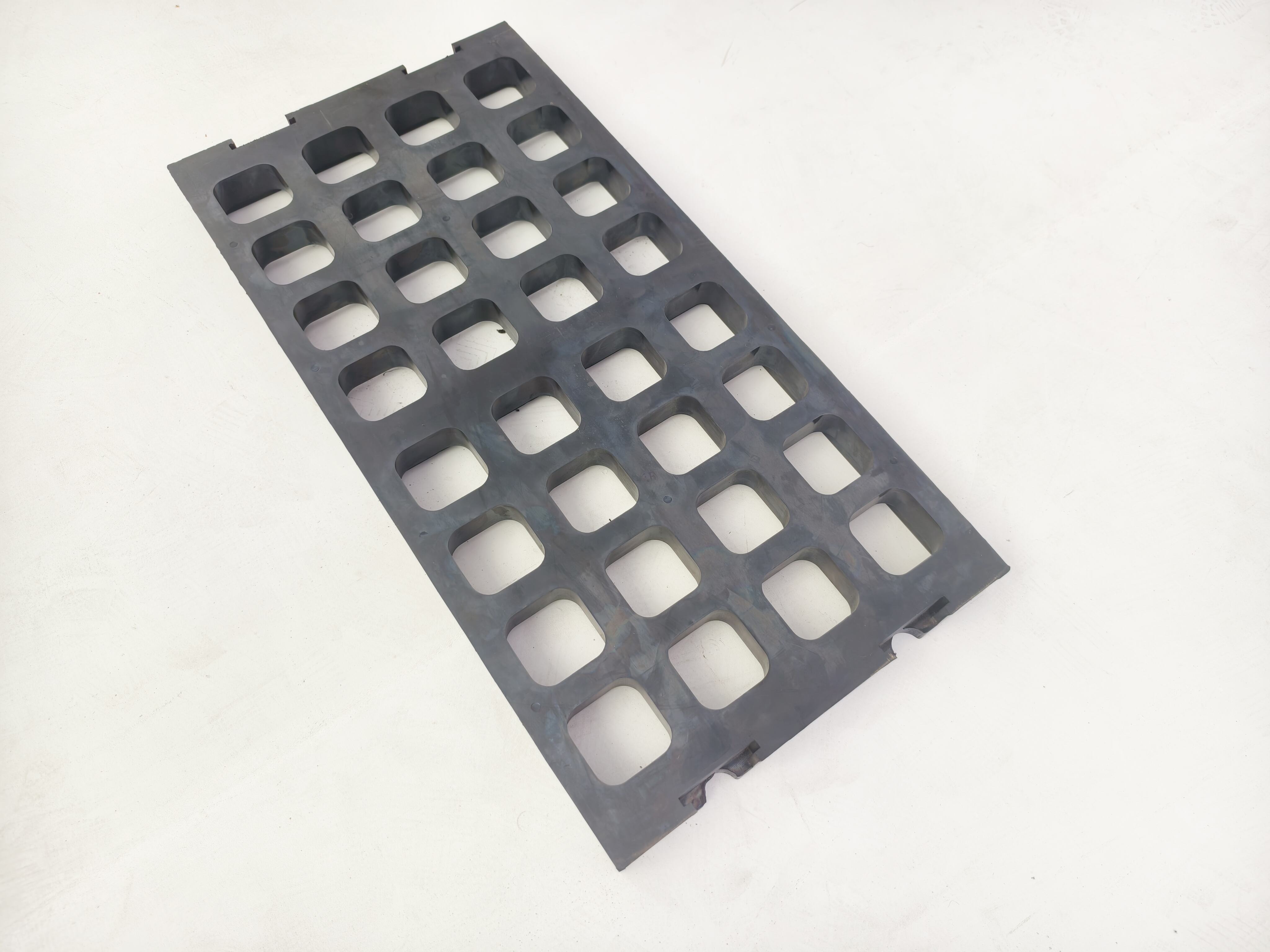

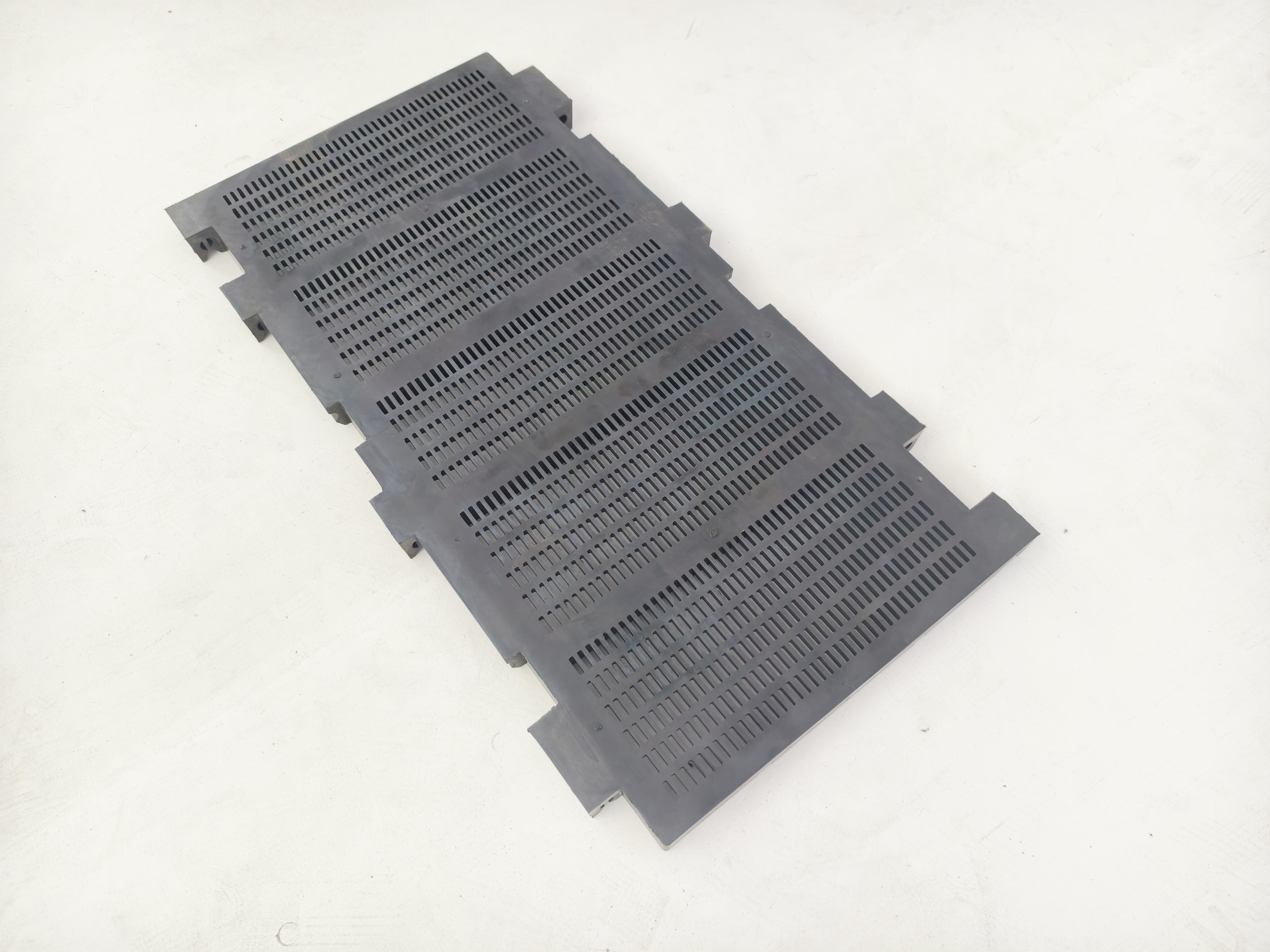

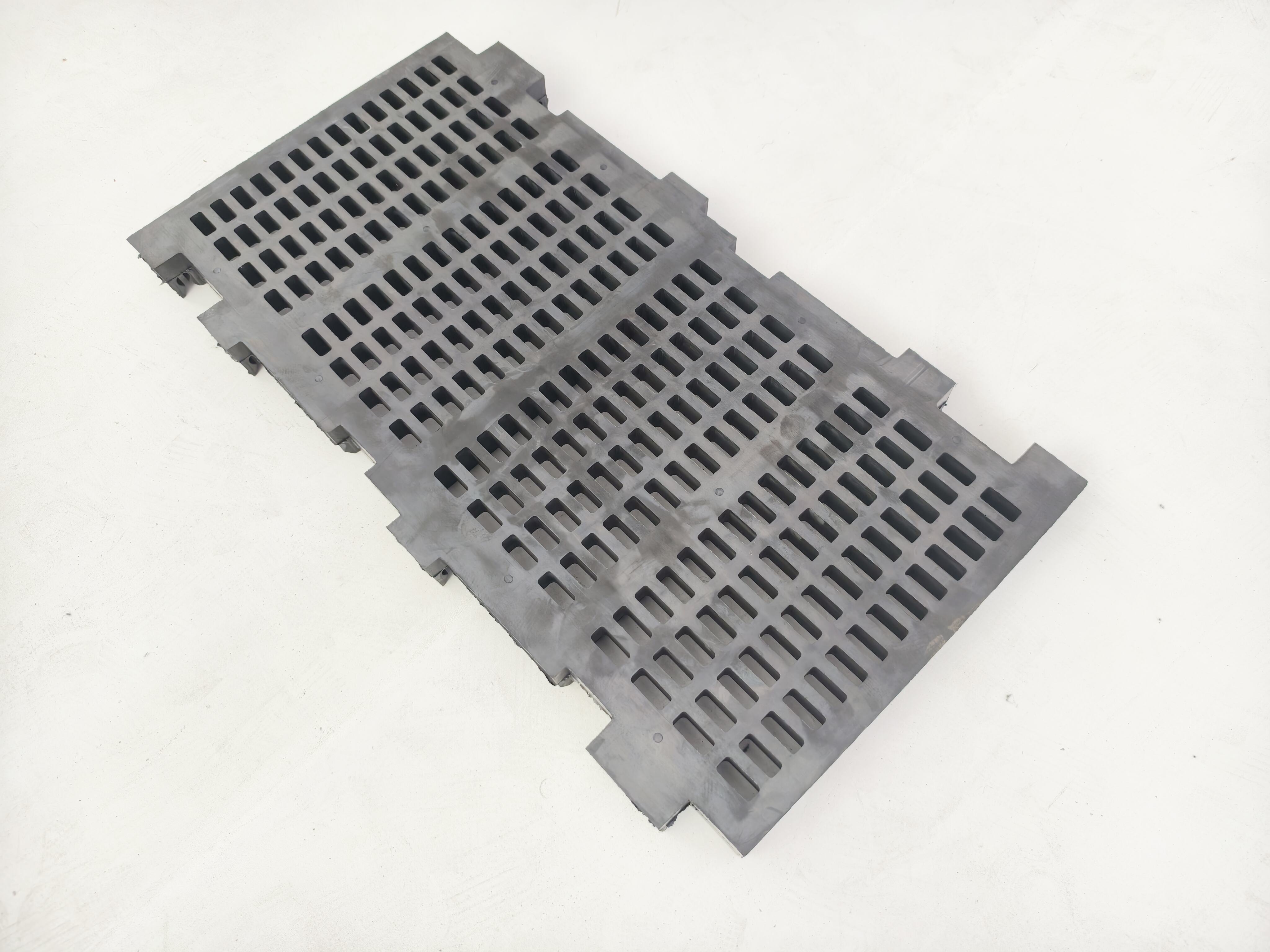

| Rubber sieve plate | Rubber sieve plate | Rubber sieve plate |

|

|

|

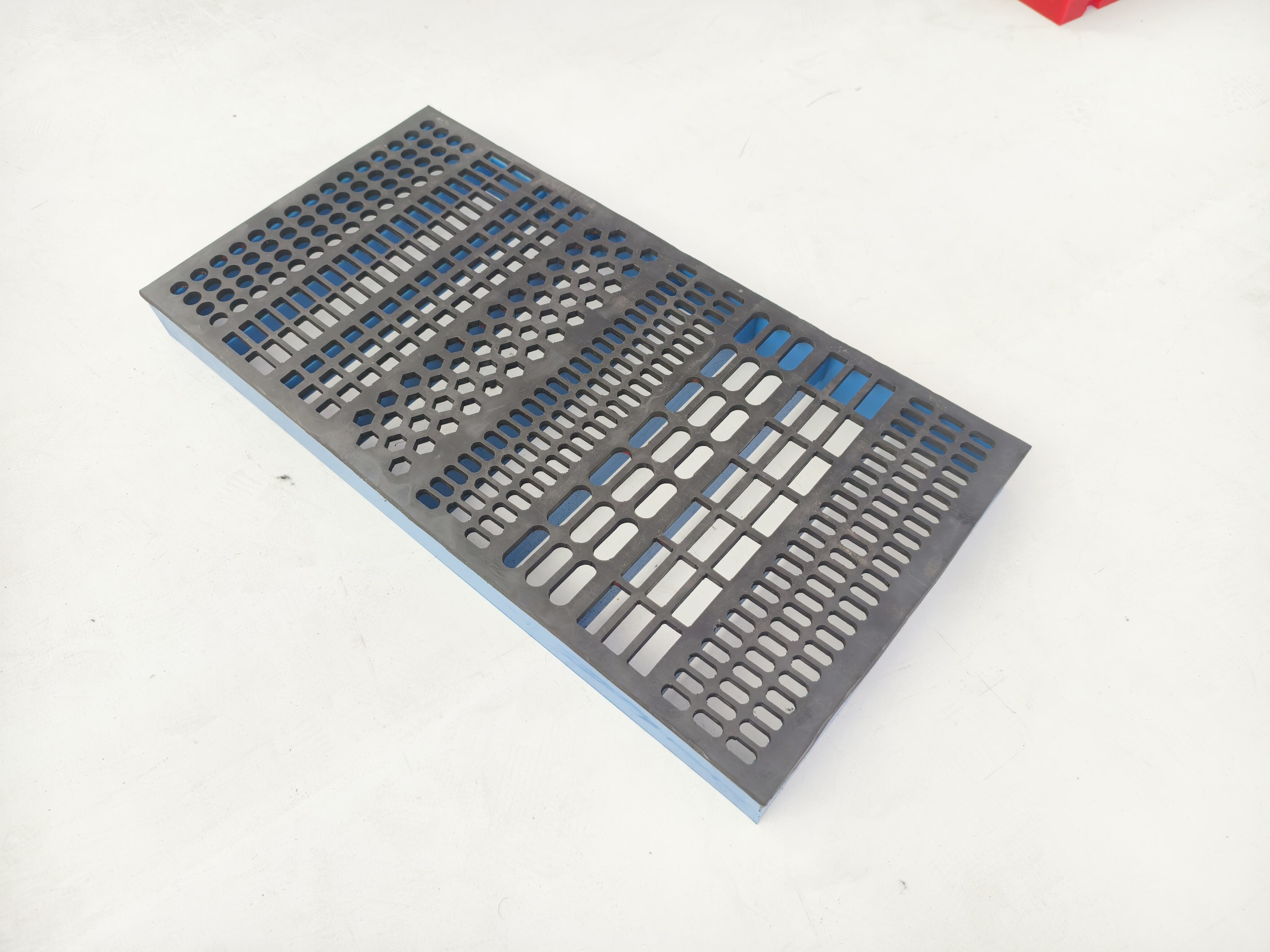

| Polyurethane rubber composite sieve plate | Rubber sieve plate | |

|

|

Vibrating rubber screen mesh is a game-changer for industries requiring robust and flexible material separation. Engineered from premium-grade rubber compounds, these screens excel in high-impact environments, offering unmatched durability, vibration resistance, and precise particle sizing. Whether for mining, aggregate processing, or recycling, our rubber screen mesh ensures longevity, reduced maintenance costs, and seamless operation under extreme conditions.

✅ High Elasticity & Flexibility

Natural rubber’s elasticity absorbs vibrations and shocks, minimizing equipment wear and extending screen lifespan.

✅ Abrasion & Impact Resistance

Withstands heavy loads and abrasive materials like rocks, ores, and recycled concrete without tearing or deformation.

✅ Anti-Blinding & Self-Cleaning

Smooth surface and dynamic vibration prevent material buildup, maintaining consistent screening efficiency.

✅ Corrosion & Weather Resistance

Resists moisture, UV exposure, and mild chemicals, ideal for outdoor or humid environments.

✅ Customizable Designs

Available in various mesh sizes (1mm–50mm), thicknesses (5mm–30mm), and panel shapes to fit any vibrating screen system.

✅ Noise Reduction

Rubber’s damping properties reduce operational noise by up to 50%, enhancing workplace safety.

Mining & Quarrying: Screen coal, iron ore, limestone, and crushed aggregates.

Recycling Plants: Separate metals, plastics, and construction debris.

Construction: Grade sand, gravel, and concrete materials.

Agriculture: Filter grains, seeds, and fertilizers.

Chemical Processing: Handle corrosive or wet materials safely.

Technical Specifications

|

|

Maximum Feeding Particle Size Range |

0.1-250mm |

Maximum Drop Height |

300-650mm |

Applications |

Comprehensive wet/dry screening |

Hardness |

Shore A 70/80/ 90(±5) |

Thickness |

40-60mm |

Certifications |

ISO 9001, CE, RoHS |