PIPO Polyurethane Screen Mesh is a cutting-edge screening solution designed for demanding industrial applications, including mining, coal processing, quarrying, and construction. Crafted from premium polyurethane (PU) elastomers, this screen mesh excels in wear resistance, corrosion resistance, and longevity, outperforming traditional metal and rubber screens. With customizable aperture sizes (e.g., 9mm square holes) and structural designs, it ensures precise grading and high throughput for dry or wet materials.

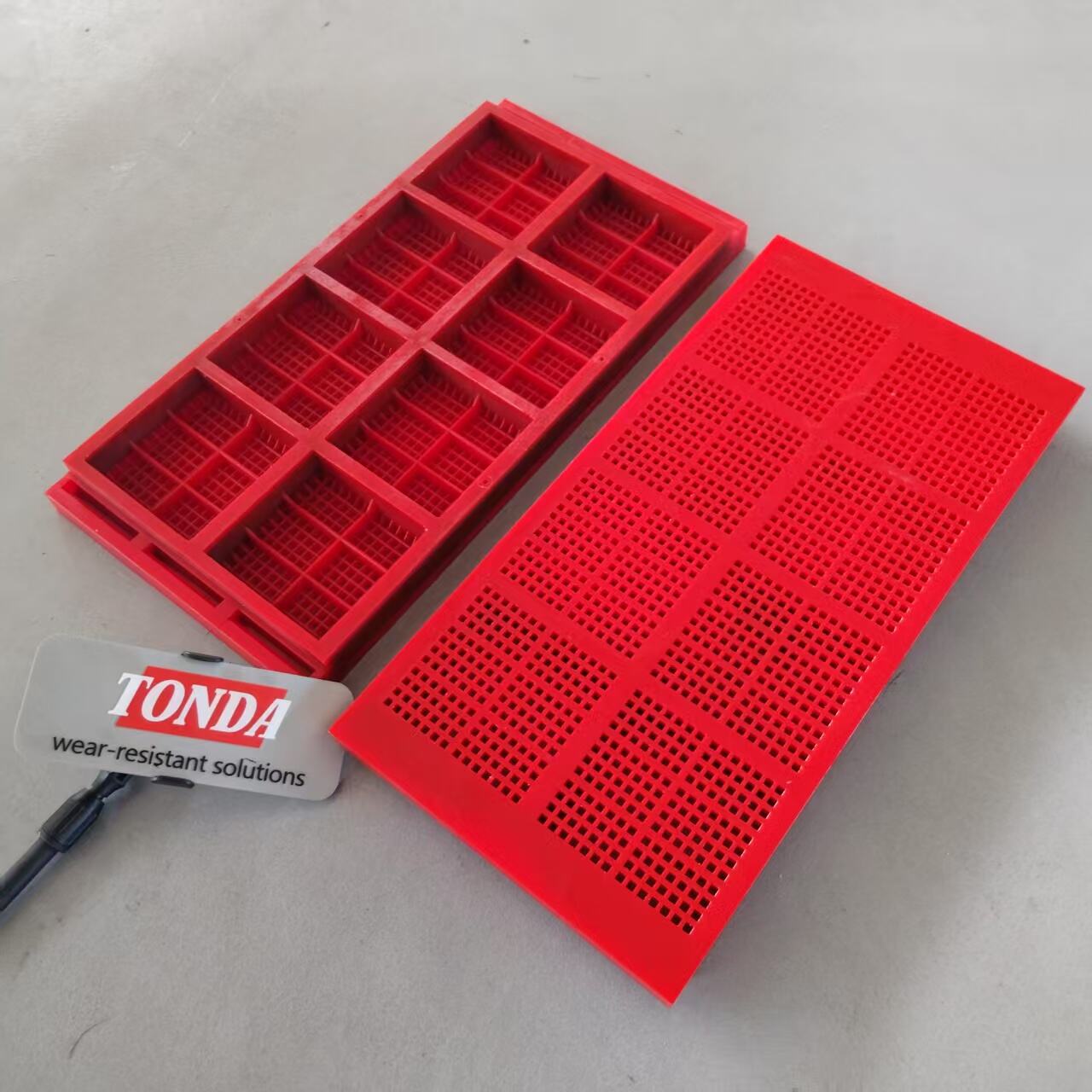

| PIPO | PIPO type sieve plate-305*305 | PIPO blind plate-305*610 |

|

|

|

| PIPO type sieve plate-305*610 | PIPO perforated sieve plate -305 * 610 | PIPO sieve plate -610 * 610 |

|

|

|

Product Overview

PIPO Polyurethane Screen Mesh is a cutting-edge screening solution designed for demanding industrial applications, including mining, coal processing, quarrying, and construction. Crafted from premium polyurethane (PU) elastomers, this screen mesh excels in wear resistance, corrosion resistance, and longevity, outperforming traditional metal and rubber screens. With customizable aperture sizes (e.g., 9mm square holes) and structural designs, it ensures precise grading and high throughput for dry or wet materials.

Key Features & Benefits

Superior Durability

8–10x Longer Lifespan: Engineered with high-abrasion-resistant polyurethane and reinforced steel wire cores, PIPO screens last 8–10x longer than steel screens and 3x longer than stainless steel alternatives.

Impact & Tear Resistance: Withstands heavy loads and harsh operating conditions, minimizing downtime and replacement costs.

High Screening Efficiency

Anti-Blocking Design: Unique 140° tapered apertures and elastic polyurethane material prevent clogging, even with sticky or damp materials like coal or wet ores.

Self-Cleaning Effect: Secondary harmonic vibrations during operation dislodge trapped particles, maintaining consistent throughput.

Noise Reduction & Environmental Safety

Reduces operational noise by 5–20 dB compared to metal screens, ensuring compliance with workplace safety standards.

Non-toxic, flame-retardant, and resistant to oils, chemicals, and extreme temperatures (-40°C to 80°C).

Lightweight & Energy-Saving

Low density (1.32 kg/m³) reduces load on vibrating screens, cutting energy consumption by up to 30% and extending equipment life.

Easy Installation & Customization

Flexible mounting options (bolted, hook-type, or tension-clamped) ensure compatibility with all vibrating screen models.

Customizable aperture shapes (square, rectangular, round) and sizes (0.1–170mm) to meet specific grading requirements.

Applications

Mining: Ideal for grading iron ore, copper, limestone, and granite.

Coal Processing: Efficient dewatering and desliming in coal preparation plants.

Aggregates & Quarries: High-precision screening of sand, gravel, and crushed stone.

Recycling & Waste Management: Separation of construction debris and industrial waste.

Technical Specifications

| Maximum Feeding Particle Size Range | 0.1-250mm |

| Maximum Drop Height | 300-650mm |

| Applications | Comprehensive wet/dry screening |

| Hardness | Shore A 70/80/ 90(±5) |

| Thickness | 45-60mm |

| Certifications | ISO 9001, CE, RoHS |