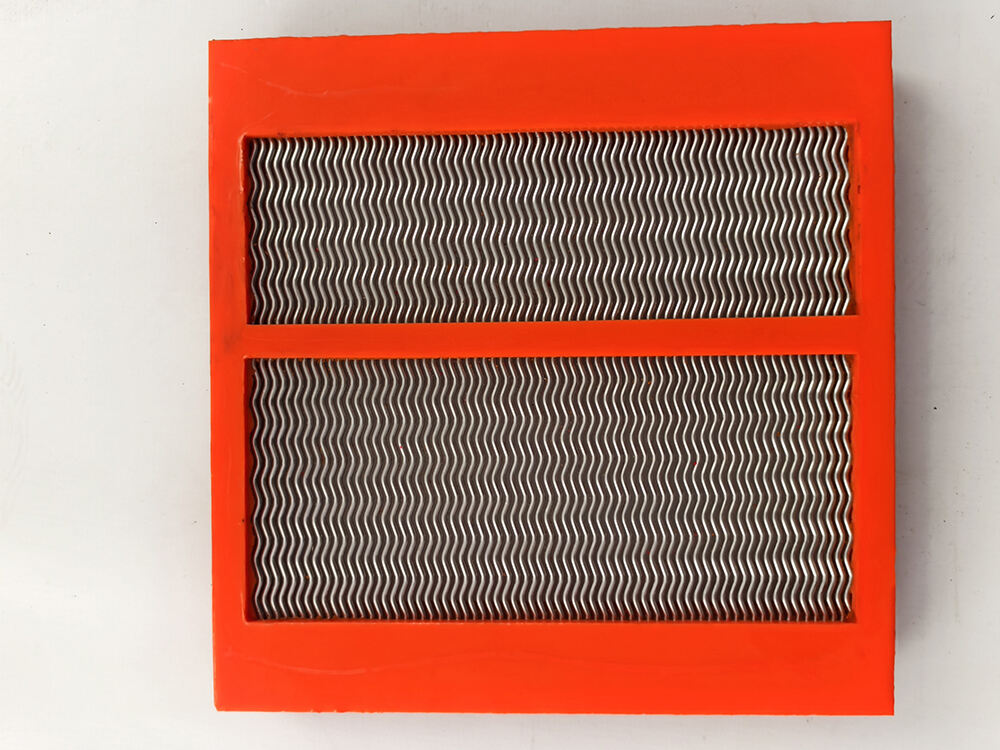

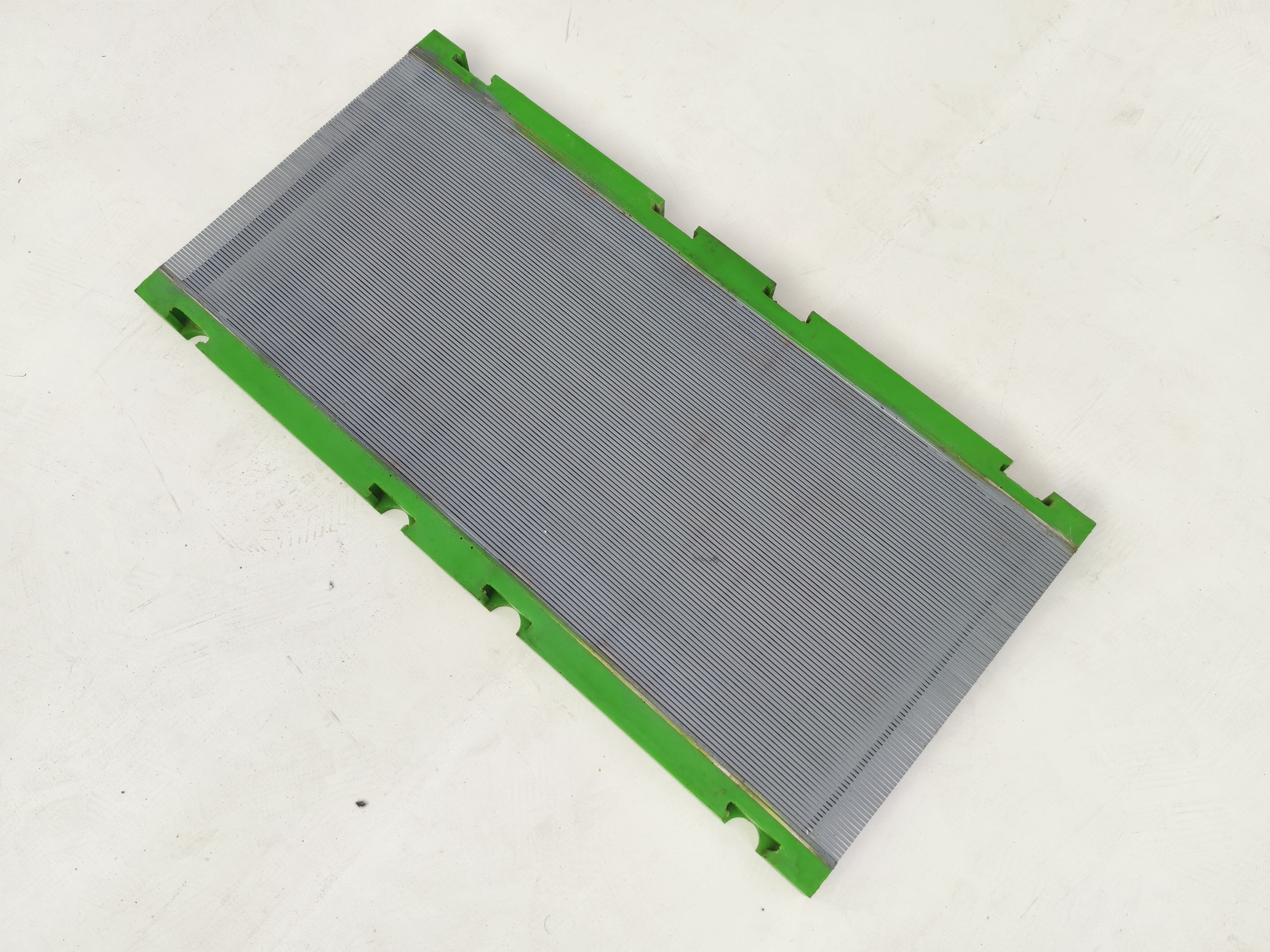

| Stainless steel sieve plate -305 * 305 | Stainless steel sieve plate -305 * 305 | Stainless steel sieve plate -305 * 610 |

|

|

|

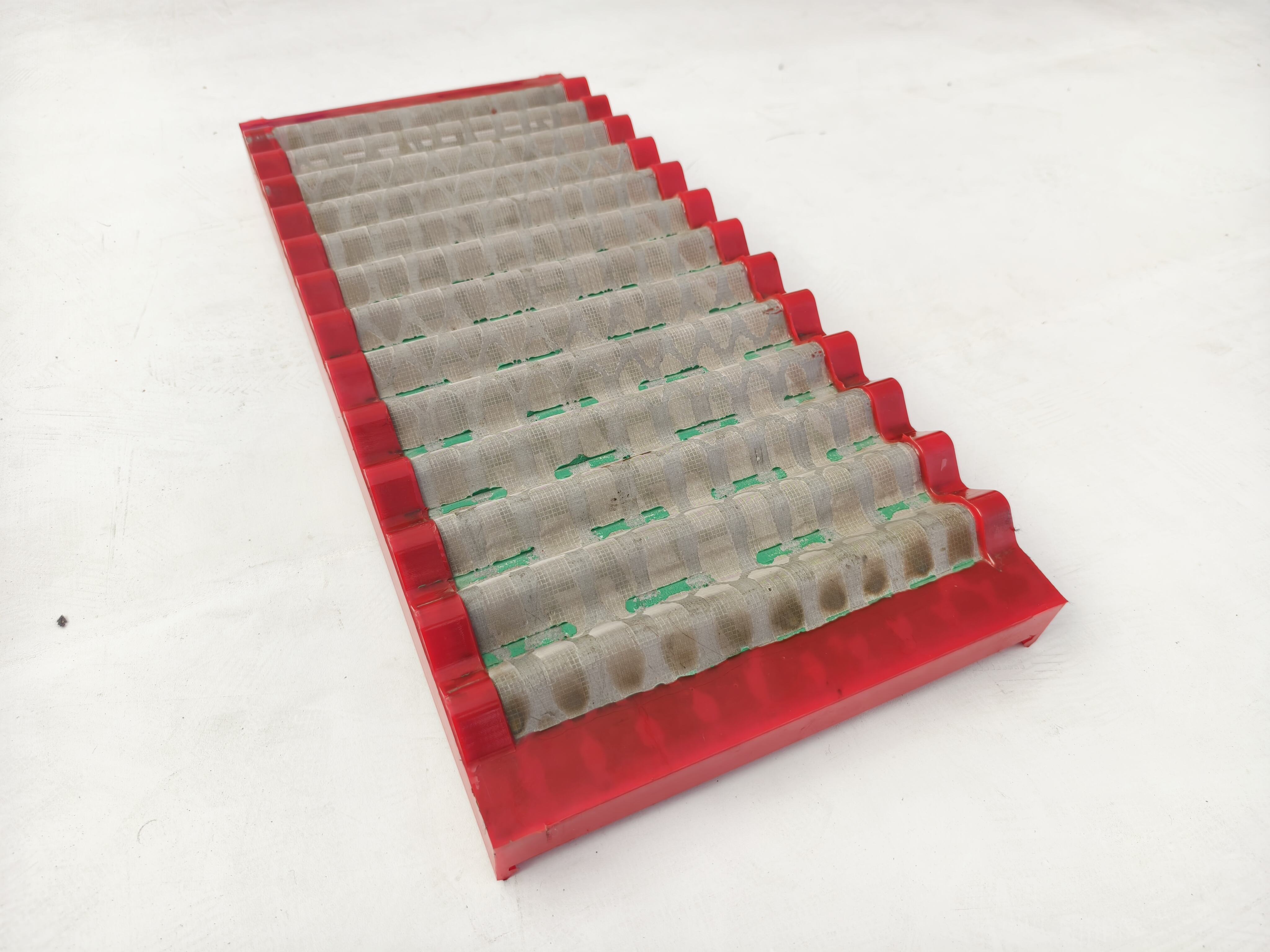

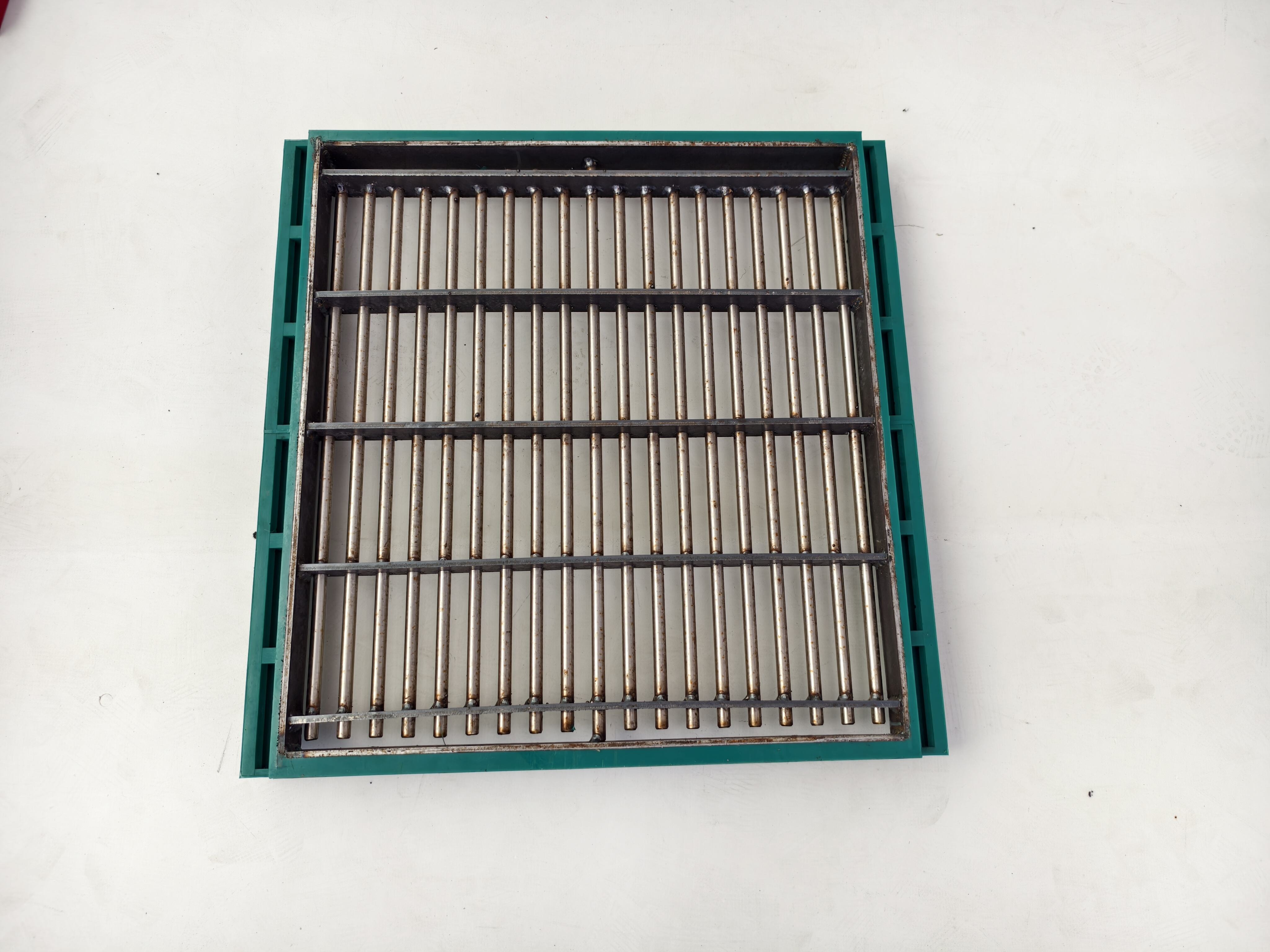

| Stainless steel sieve plate -305 * 610 | Stainless steel sieve plate | Stainless steel elastic rod sieve plate |

|

|

|

Product Overview

Metal-Bordered Polyurethane Screen Mesh is a premium industrial screening solution designed for high-intensity material separation in mining, quarrying, recycling, and aggregate processing. Combining the superior elasticity and wear resistance of polyurethane (PU) with a reinforced metal frame (e.g., stainless steel or galvanized steel edges), this hybrid design ensures exceptional structural integrity, tear resistance, and extended service life—ideal for heavy-load applications where traditional screens fail.

Key Features & Benefits

Enhanced Durability with Metal Reinforcement

Steel-Bordered Protection: The metal frame prevents edge wear and deformation, increasing lifespan by 8–10x compared to standard steel screens and 3x longer than rubber alternatives.

High Tensile Strength: Reinforced with embedded steel wires and a robust PU matrix, it withstands extreme vibration forces (up to 50G) and heavy impact loads.

Optimal Screening Efficiency

Anti-Clogging Design: Tapered apertures (e.g., 140° angle) and elastic PU material prevent material buildup, even with sticky substances like coal sludge or wet ores.

Self-Cleaning Mechanism: Harmonic vibrations during operation dislodge trapped particles, maintaining 95%+ screening accuracy and consistent throughput.

Noise Reduction & Environmental Safety

Reduces operational noise by 5–20 dB compared to metal screens, ensuring compliance with workplace safety standards.

Flame-retardant, non-toxic, and resistant to oils, chemicals, and extreme temperatures (-40°C to +80°C).

Easy Installation & Low Maintenance

Pre-Drilled Metal Edges: Simplify mounting with bolt-on or hook-type systems, compatible with all vibrating screen models (linear, flip-flow, etc.).

Lightweight PU core (density: 1.32 kg/m³) reduces equipment strain, cutting energy consumption by 30%.

Customizable Solutions

Aperture Sizes: 0.1–170mm, available in square, round, or slotted shapes.

Metal Frame Options: Stainless steel, galvanized steel, or corrosion-resistant alloys for harsh environments.

Applications

Mining & Quarries: Precision grading of iron ore, copper, limestone, and granite.

Coal Processing: Efficient dewatering and desliming in preparation plants.

Recycling: Separation of construction debris, e-waste, and industrial scrap.

Aggregate Production: High-capacity screening of sand, gravel, and crushed stone.

Technical Specifications

|

|

Maximum Feeding Particle Size Range |

0.1-250mm |

Maximum Drop Height |

300-650mm |

Applications |

Comprehensive wet/dry screening |

Hardness |

Shore A 70/80/ 90(±5) |

Thickness |

30-60mm |

Certifications |

ISO 9001, CE, RoHS |

Why Choose Our Metal-Bordered PU Screen Mesh?

Cost Efficiency: Higher initial cost but 3–5x lower total ownership cost due to reduced replacements and downtime.

Global Trust: Used in mining and industrial projects across 20+ countries.

Technical Support: OEM/ODM customization, bulk pricing, and 24/7 after-sales service.

Installation Guidelines

Ensure uniform tensioning (50N recommended) to avoid uneven wear.

Use corrosion-resistant fasteners for metal edges in humid or acidic environments.

Regularly inspect frame alignment and PU surface for early wear detection.