High-efficiency polyurethane screen panels are revolutionizing material separation in demanding industries. Crafted from advanced polyurethane compounds, these sieve plates deliver unparalleled durability, wear resistance, and screening accuracy. Ideal for mining, aggregate processing, recycling, and construction, our polyurethane screen panels ensure minimal downtime and extended service life, translating to significant cost savings.

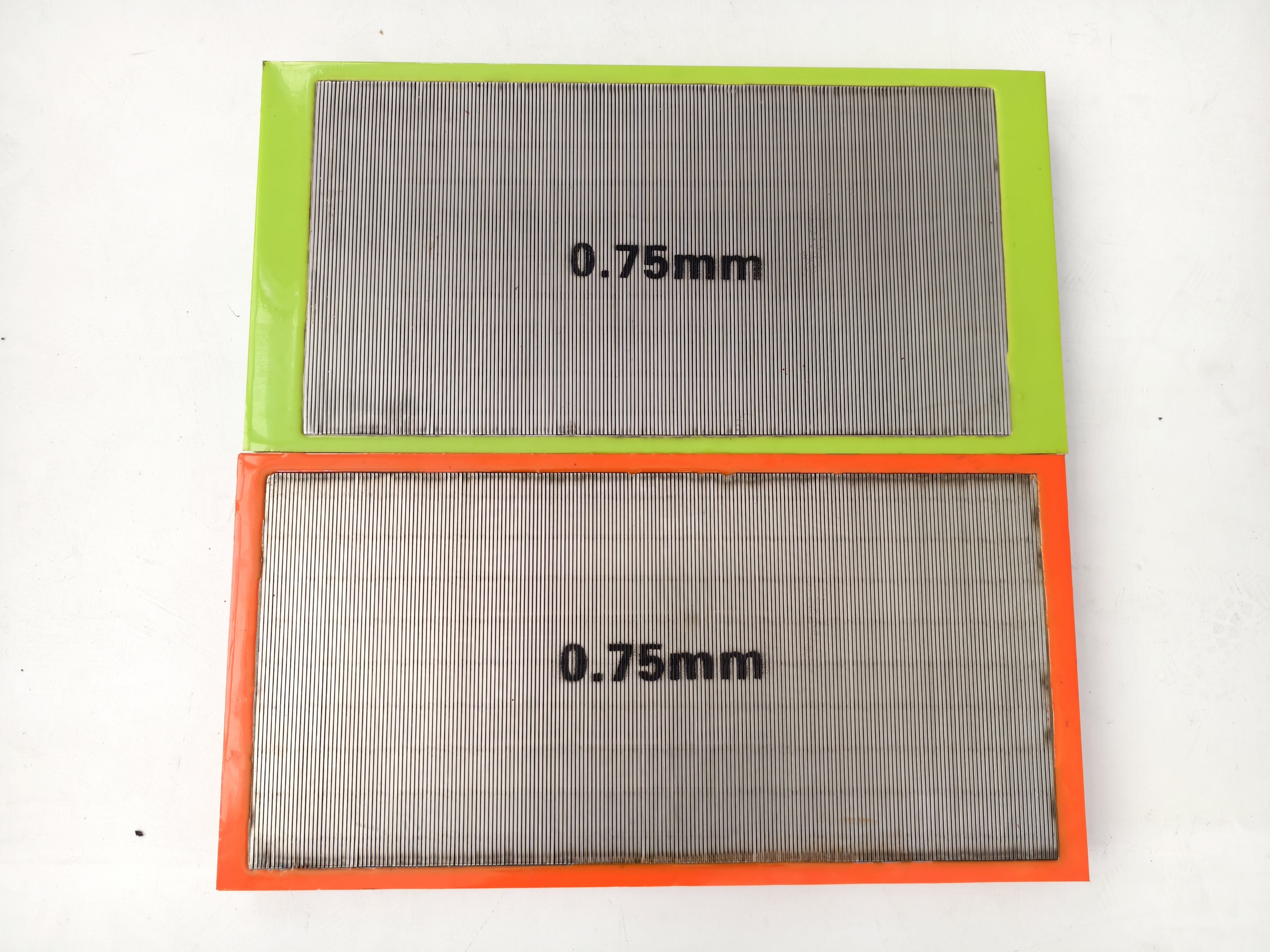

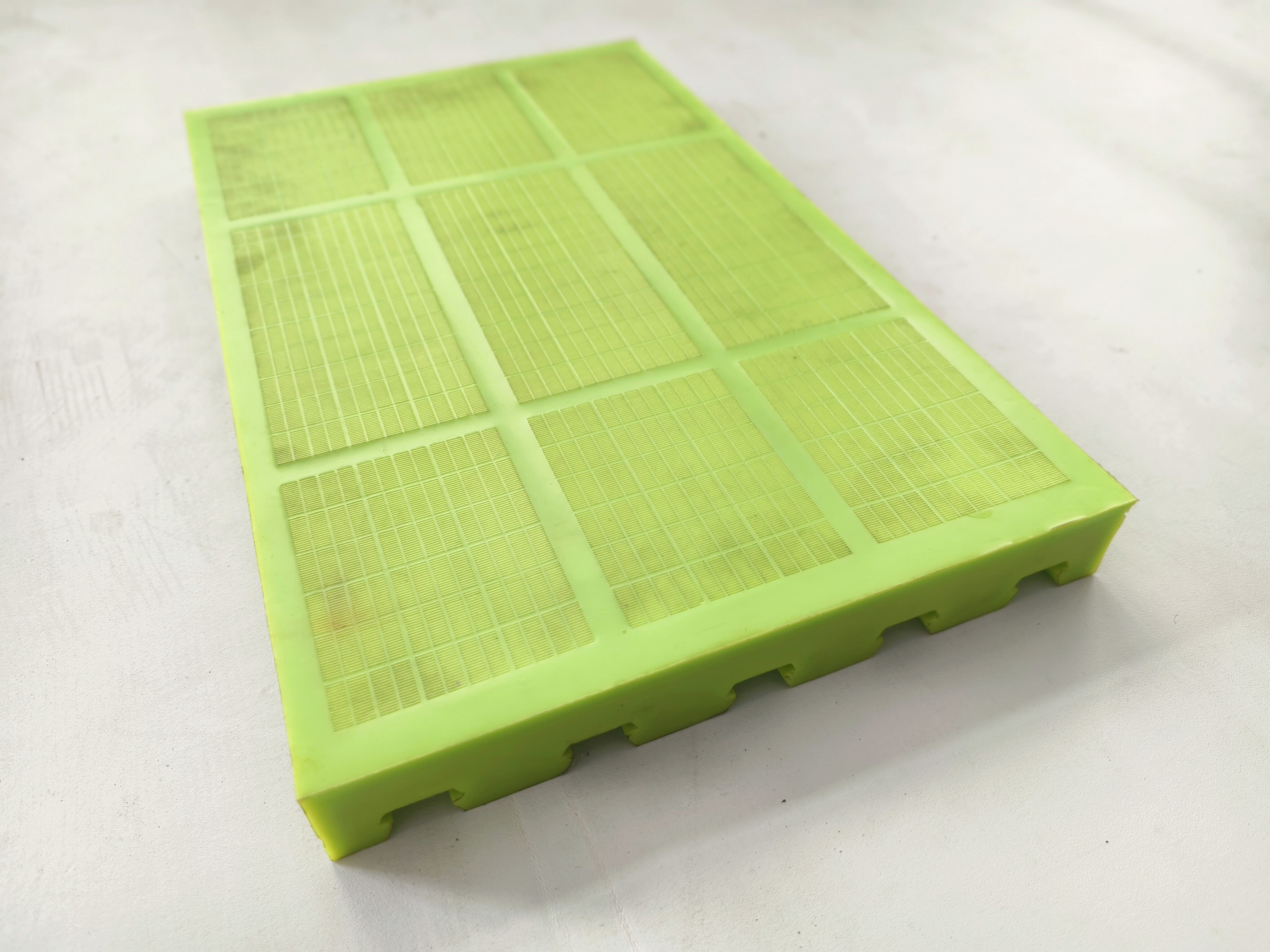

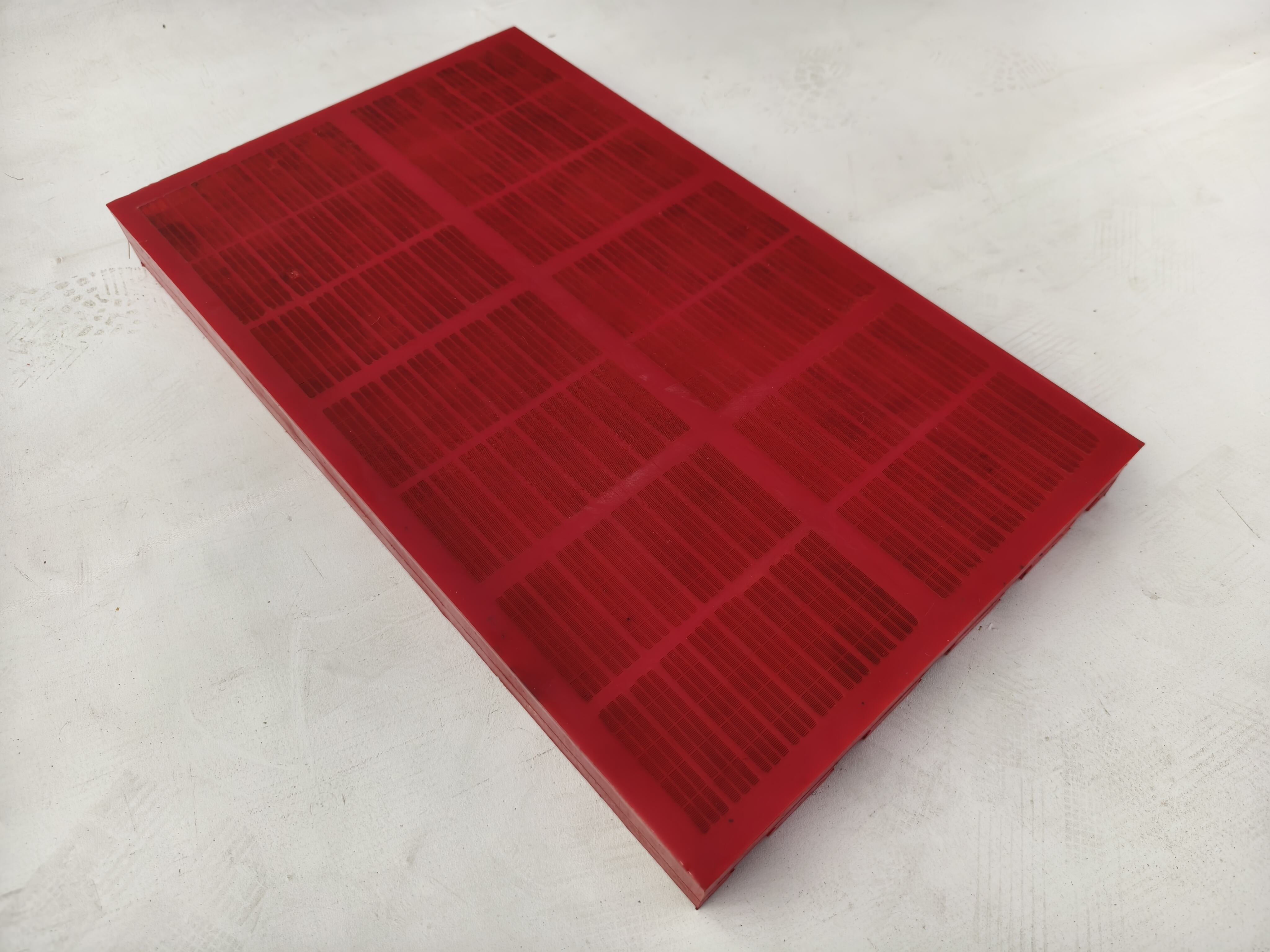

| Efficient sieve plate - comparison of opening rate | Efficient sieve plate -305 * 500 | Efficient sieve plate -305 * 610 |

|

|

|

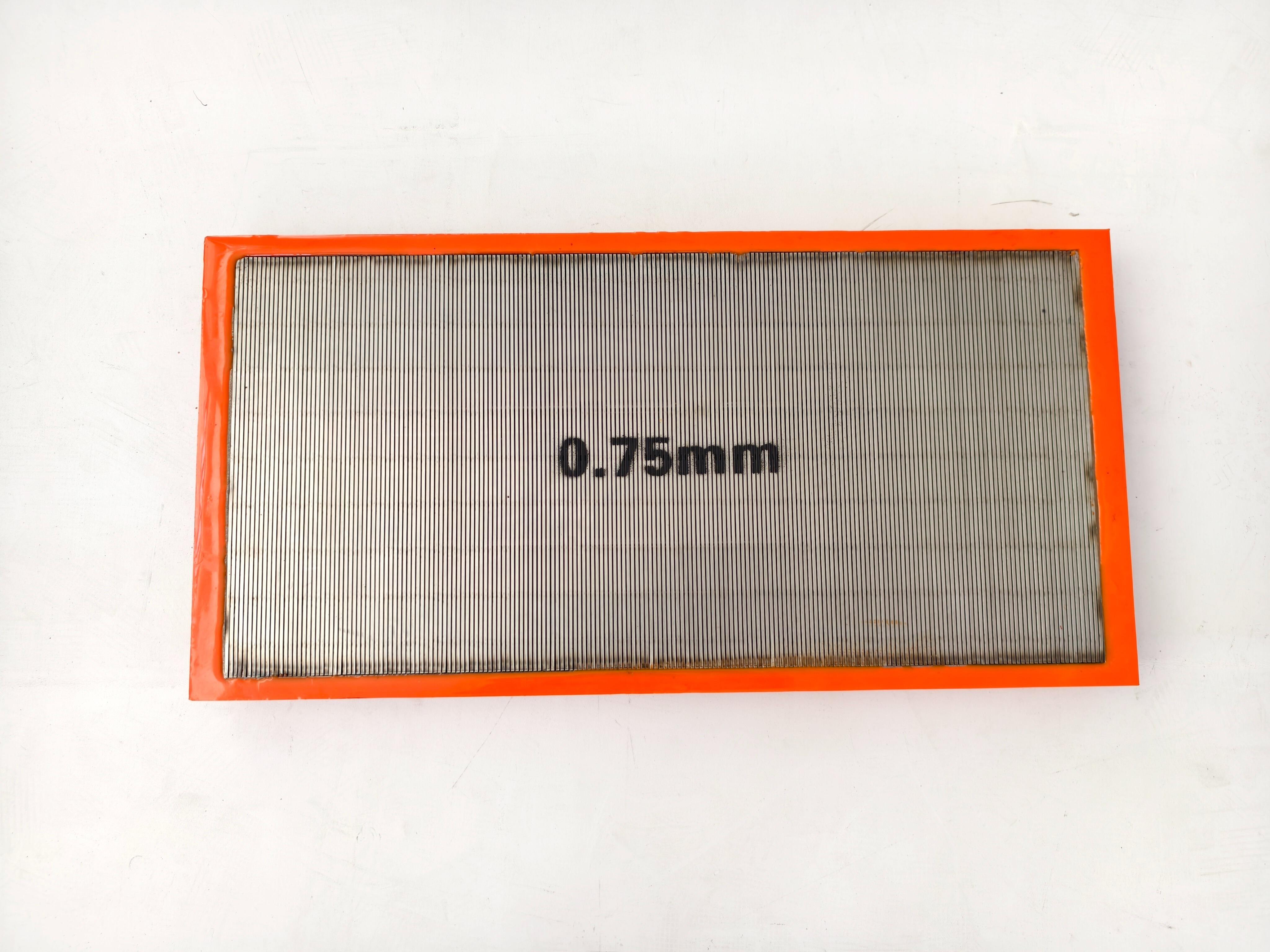

| Efficient sieve plate -610 * 610 | Efficient stainless steel sieve plate -305 * 610 | |

|

|

High-efficiency polyurethane screen panels are revolutionizing material separation in demanding industries. Crafted from advanced polyurethane compounds, these sieve plates deliver unparalleled durability, wear resistance, and screening accuracy. Ideal for mining, aggregate processing, recycling, and construction, our polyurethane screen panels ensure minimal downtime and extended service life, translating to significant cost savings.

✅ Superior Wear Resistance

Polyurethane’s exceptional abrasion resistance outperforms traditional steel or rubber screens, even under high-impact conditions.

✅ Anti-Clogging Design

Openings remain clear thanks to smooth surfaces and optimized aperture geometry, enhancing screening efficiency by up to 30%.

✅ Corrosion & Chemical Resistance

Withstand harsh environments, including exposure to acids, alkalis, and moisture, without degradation.

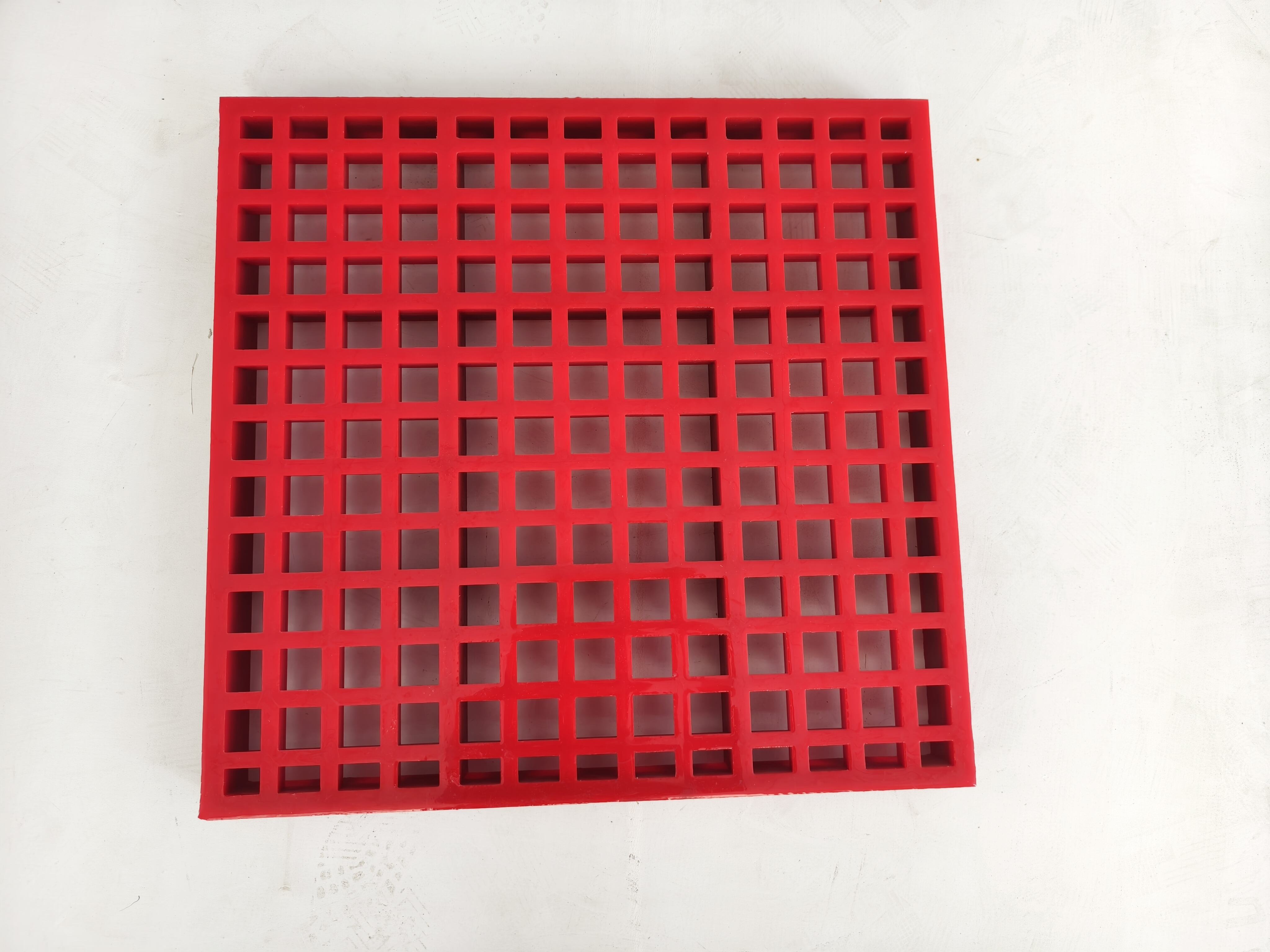

✅ Customizable Sizes & Patterns

Available in tailored dimensions (e.g., 300mm–2000mm) and aperture shapes (square, slot, round) to match your specific needs.

✅ Noise Reduction

Polyurethane’s elasticity reduces operational noise, improving workplace safety and compliance.

✅ Lightweight & Easy Installation

20–40% lighter than metal alternatives, simplifying handling and reducing labor costs.

Mining & Quarrying: Efficiently screen coal, iron ore, limestone, and aggregates.

Recycling: Separate plastics, metals, and construction waste.

Construction: Grade sand, gravel, and concrete materials.

Agriculture: Sort grains, seeds, and fertilizers.

Material: High-grade polyurethane (Shore hardness: 70A–95A).

Aperture Sizes: 0.1mm–100mm (customizable).

Temperature Range: -40°C to +80°C.

Load Capacity: Up to 15 tons/hour per m².

Certifications: ISO 9001, MSHA compliant.

🔹 Proven Performance: Trusted by global mining and construction leaders.

🔹 Fast Delivery: Standard and custom orders shipped within 7–15 days.

🔹 24/7 Technical Support: Expert guidance for installation and optimization.

🔹 Cost-Effective: 3–5x longer lifespan than rubber screens.

Technical Specifications

| Maximum Feeding Particle Size Range | 0.1-250mm |

| Maximum Drop Height | 300-650mm |

| Applications | Comprehensive wet/dry screening |

| Hardness | Shore A 70/80/ 90(±5) |

| Thickness | 40-60mm |

| Certifications | ISO 9001, CE, RoHS |